4x Kute rims 22 for MERCEDES G AMG W460 W461 W463 W464 black G500 - black - LB4011

- The RacingLine rim features an industrial design reserved for Mercedes. Detailed information on the possibility of using a substitute can be found in the Store Regulations

17 YEARS ON THE MARKET

17 YEARS ON THE MARKET

Together, we develop the Polish economy

SECURITY

SECURITY

The regulations meet the Trusted Shop quality criteria

QUALITY CERTIFICATE

QUALITY CERTIFICATE

Alloy wheels have ISO, VIA JWL certificates proving their high quality

GUARANTEED QUALITY

GUARANTEED QUALITY

Aluminum Rims are covered by a 3-year warranty

STATIONARY SHOPS

STATIONARY SHOPS

Opportunity to look at the goods closely, direct contact with an expert

In a set

Forged Alloy Wheels 22" GT Fusion LB4011: Maximum Durability and Style!

Rims made of forged, aerospace-grade aluminum alloy 6061-T6. This is the most advanced technological process. The result is a product with exceptional hardness, damage resistance, and low weight 14,6 kg. Forged rims 22" are characterized by outstanding elasticity, meaning that under loads (up to approximately 100 tons per cm²), they do not undergo permanent deformations or cracks. They are manufactured with exceptional precision, exclusively for the most demanding customers.

By purchasing this product, you will receive from us:

✅ 4 x new aluminum rims,

✅ 4 x manufacturer's caps,

✅ 4 x centering rings (if required),

✅ 4 x chrome valves(❌ these are not TPMS sensors)➡️ TPMS sensors

❌ IMPORTANT! The set does not include screws/nuts ➡️ accessories

Give your car a unique look with 22-inch LB4011 wheels in color BL - BLACK. Designed for a perfect fit, these 10" wide wheels with a 5x130 bolt pattern and a 30 offset (ET) are a perfect match for models such as MERCEDES G AMG W460 W461 W463 W464 black G500.

Thanks to precise craftsmanship and rigorous quality testing, our wheels offer excellent fit and durability. Compatible with TPMS sensors, they ensure safety and convenience. These 22-inch alloy wheels are the perfect choice for drivers who value style, quality, and safety. Check the full list of compatible models in the "Fitment Guarantee" section and order your wheels today!

Forged Wheels 22" GT Fusion – For Motorsport and Everyday Use.

Forged wheels GT Fusion are a perfect combination of durability, lightness, and precision craftsmanship. They are made from high-quality aluminum alloy – 6061-T6. This material is characterized by high hardness, strength, corrosion, and oxidation resistance, and excellent welding properties. It is used in industries such as aerospace, military, shipbuilding, and construction.. Thanks to advanced forging technology, these wheels feature exceptional durability and excellent mechanical properties, making them the ideal choice for the most demanding drivers – whether in sports, luxury, or utility vehicles.

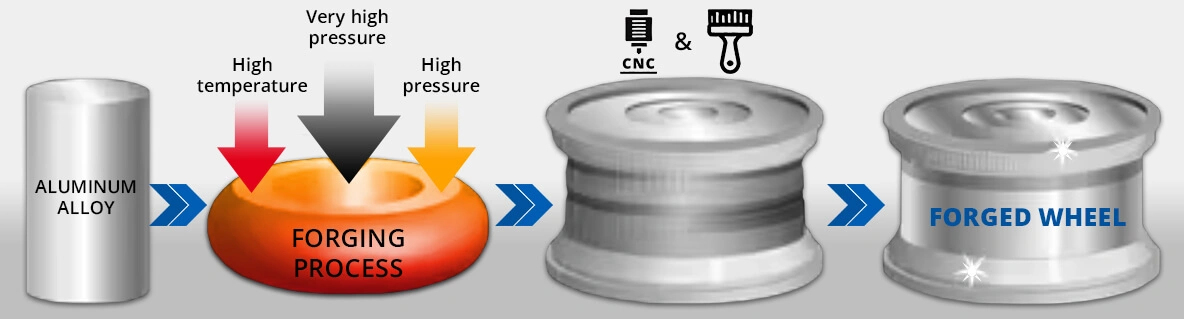

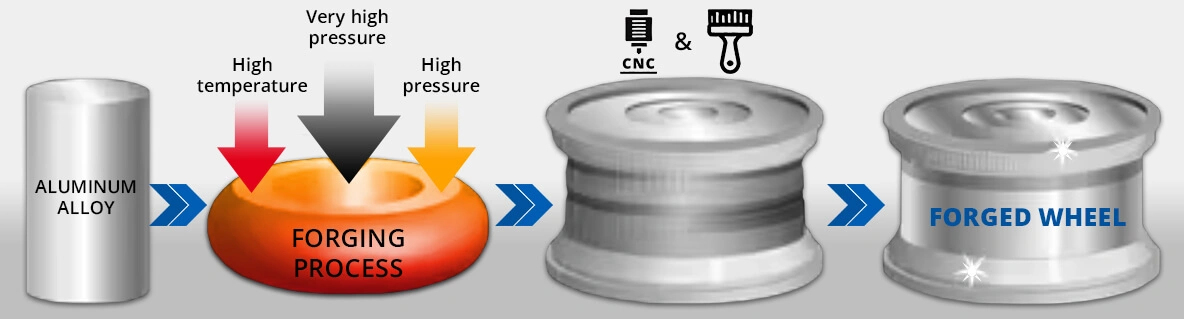

Production Process of Forged Wheels.

Thanks to an advanced production process, forged wheels are extremely lightweight, durable, and resistant to dynamic loads. To achieve the highest standards, each wheel GT Fusion undergoes complex production processes consisting of several stages:

1. Raw aluminum material is first heated to a high temperature to facilitate plastic forming.

2. The forging process follows – under enormous pressure, the material is formed into the shape of a wheel using a hydraulic press with high force, giving it remarkable density and strength. This process ensures an ideal molecular structure, resulting in exceptional lightness and durability of the wheel.

3. The wheel goes through heat treatment processes to further enhance its mechanical properties.

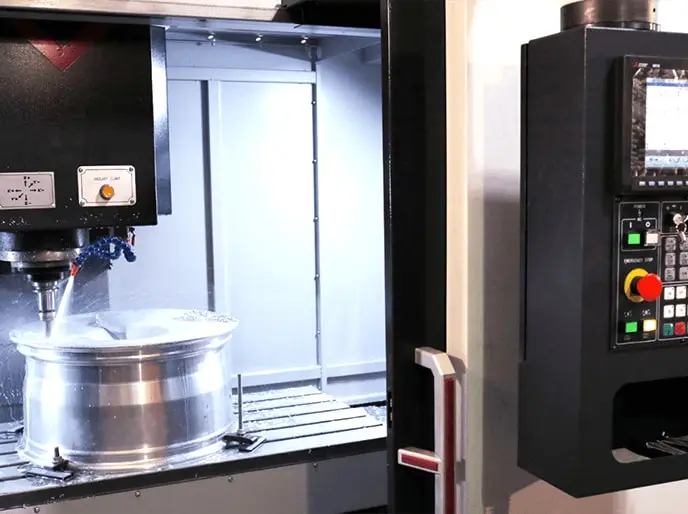

4. Final stages include precise machining, finishing, and painting, giving the wheel its final appearance and specifications.

Forged wheels GT Fusion are an investment in quality, durability, and exceptional aesthetics, satisfying every automotive enthusiast. If budget is not a constraint, forged aluminum wheels are an excellent choice.

Premium wheels GT Fusion – the future of the alloy wheel market.

Based on our many years of experience in the market and our knowledge of the automotive and wheel industries, we have created our own brand – GT Fusion. GT Fusion alloy wheels are characterized by the highest quality of craftsmanship, as confirmed by ISO, VIA, JWL certificates and a long warranty period. During the production process, each wheel undergoes detailed quality control and rigorous durability tests, ensuring that 100% of our products are of high quality. We want every driver to enjoy not only the reliability of our products but also their unique style, which will make their car stand out on the road.

Testing and research ensure high-quality alloy wheels

The production process of GT Fusion wheels ends with a series of tests, during which numerous tests are conducted. Only alloy wheels that have passed all the following tests are introduced to the market:

✅ tensile test

✅ radial and dynamic balancing test - with deviations up to 0,6 mm (PIMOT recommendations allow 0.8 mm)

✅ verification of the center hole - permissible tolerance up to 0,3 mm

✅ corrosion resistance test

✅ structural integrity and lack of micro-cracks are diagnosed using an X-ray machine

✅ leak test

✅ paint coating evaluation

✅ load-bearing capacity test

✅ bending resistance test under twisting

✅ rolling resistance test

✅ impact test

✅ variable torque test

Alloy wheels manufactured in certified factories.

The factories where GT Fusion alloy wheels are manufactured have obtained certifications: American Smithers, TUV NORD (ISO9001, IATF16949), ISO14001, ISO45001, ISO50001, American DOT-T, Japanese VIA, Brazilian INMETRO. The specifications define the quality system requirements for products in the fields of design, production development, installation, and servicing in the automotive industry. Most production processes are fully automated. Advanced forging technology combined with international automotive industry standards enables the production of reliable products – high-quality GT Fusion alloy wheels.

Fitment Guarantee

We continuously expand our offer and update the database so you can easily find the right wheels for your car model. If you find your model in the "Fitment Guarantee" list, you can be sure that you are buying the correct wheels. However, if you have any doubts or questions, feel free to contact our Customer Service Department, where you will get answers to most questions.

We select alloy wheels according to the manufacturer's catalog parameters. For some car models or wheels, it may be necessary to use spacers, and special bolts/nuts, which you can easily find in our store in the "Accessories" section.

The risk of error is minimal, but before installation, check whether the wheels fit your car, have no deviations, do not rub against suspension parts, and do not protrude beyond the fender. It is important to verify the goods BEFORE fitting the tires onto the wheels. Fitting tires is unnecessary and will prevent the correct diagnosis of the product. Alloy wheels should be fitted on both axles of the vehicle. However, if you visit a service/shop, inform the tire fitter to perform the above tasks first.

Accessories in one of the four boxes

Upon receiving your order, check if the package contains all the products you purchased. Caps and other accessories may be attached to the bottom of the box or be in one of the four boxes.

Read on the blog LadneFelgi.pl

Tech specs:

The model:determines the appearance of the rim. By entering the model in the LadneFelgi.pl store search engine, you can search for rims in different colors and with other parameters.

Size: is the diameter of the rim in inches (1 inch = 2.54 cm). Possible sizes are predetermined by the car manufacturer. It is not allowed to use smaller rims than provided by the manufacturer.

Rim width: is measured between the rim flanges. The dimension is in inches. When choosing tires, take into account the width of the rim and the car manufacturer's recommendations.

Wheel PCD: determines the number and spacing of mounting holes. This is the diameter of the circle with the centers of these mounting holes. The diameter of the circle is given in millimeters.

ET, offset: is not a strictly defined parameter, such as spacing. It depends on the width of the rim. ET is given in mm. The smaller the offset, the more the rim is, which increases the wheelbase, positively influencing the car's stability. The service book or ASO provides only the parameters of the currently installed rims.

Center bore: it is the dimension of the rim center hole diameter given in mm. If the car has a smaller hub diameter, centering rings are used. The ring is used to center the rim in relation to the car's hub. After screwing it, no force acts on it. It is a safe solution used by all rim manufacturers.

Color: determines the colors in which the offered item was made. Pictures are taken under natural lighting.

The working shape of the screw head, must correspond to the shape of the mounting hole made in the rim. We distinguish between spherical( spherical), conical or flat sockets for flat rim holes. The standard is a cone with an angle of 60 degrees

TPMS Sensors - the parameter determines whether the TPMS pressure sensors can be used with a given rim.

Nowoczesny design

Nowoczesny design Idealne dopasowanie

Idealne dopasowanie Duża wytrzymałość

Duża wytrzymałość Wysyłka gratis w 24h

Wysyłka gratis w 24h

Indywidualny projekt

Indywidualny projekt Dedykowany opiekun

Dedykowany opiekun