How are forged rims made and are they really worth the price?

Car enthusiasts are well aware that there are several methods for producing aluminum rims. The level of sophistication and durability of the final product increases with the price, which, unfortunately, isn't always attractive. Forged rims are among the most expensive, yet also the most durable, and are considered synonymous with the highest quality and reliability. When looking to upgrade your car's alloy wheels, we often wonder if it's really worth spending so much on these rims? Are they worth it? We'll try to answer these questions below.

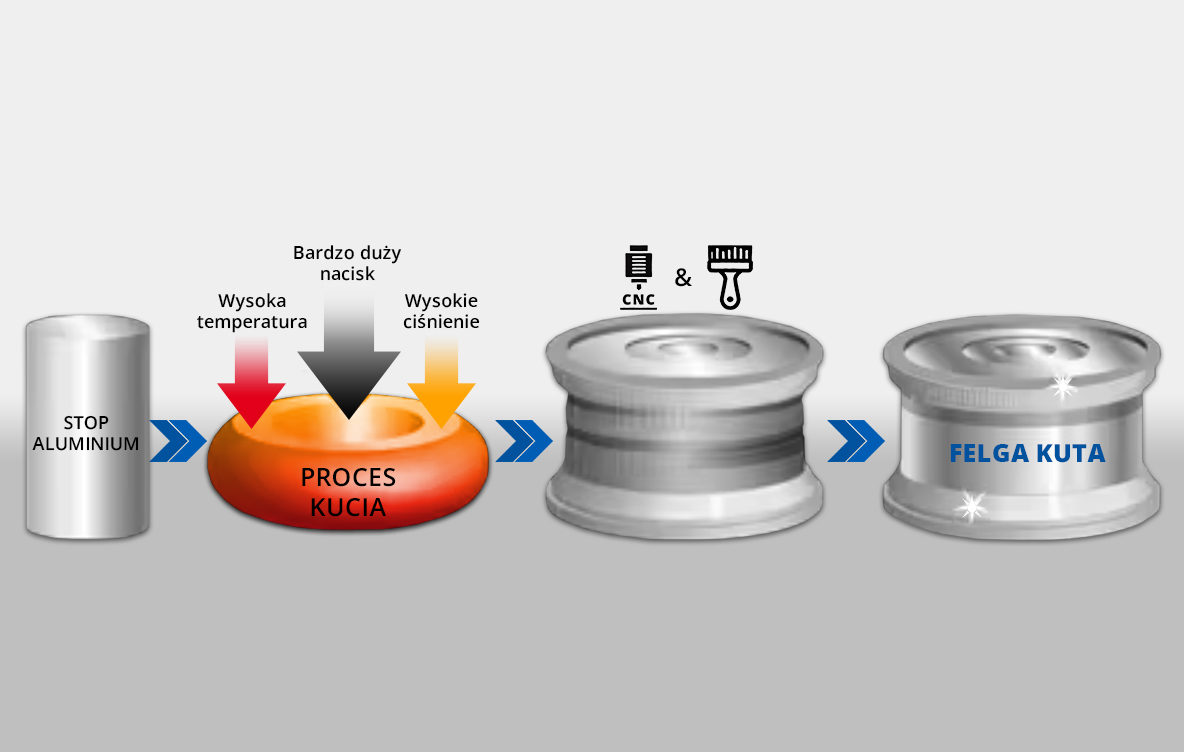

The production process of forged rims.

There are four basic methods of rim production: low-pressure, gravity, rolling, and forging . The last method, considered legendary or even perfect in some circles, guarantees a highly specialized, solid, and durable rim. As you can easily deduce, the cost of purchasing one is enormous. Forged rims command exorbitant prices, which is why they are most often found on high-end sports cars, where compromises are out of the question.

The process of creating forged wheels can be divided into several stages. The first, of course, is design. This is when we see the design, select wheel sizes, and determine the product's appearance and construction. Then comes the actual production process : heated aluminum is subjected to incredible pressure, shaping the wheel's shape . This is also where changes in the product are analyzed and stresses are detected. After the stress test, the wheel is subjected to pressure on the spokes, and critical areas are corrected. After passing these stages, the wheel becomes nearly perfect, yet the designers are once again tested, analyzing its durability, once again subjecting it to forces unheard of in everyday use. This ensures full operational readiness, even in extremely challenging conditions. Only then does the wheel reach the paint shop, where it takes on its final appearance.

An example of the production process of forged rims.

A number of advantages of rims manufactured using the forging method.

Manufacturers of forged aluminum rims cite a number of features that make them unique. The greatest advantages of this type of rim undoubtedly include:

- incredible durability and resistance to road irregularities

- lower weight and therefore greater dynamics, easier braking, less wear of suspension components

- no corrosion

- rich design

- they do not deform even in rally conditions

- higher driving comfort

Forged rims manufactured to individual order.

photo: forgiato.com

This option is designed for truly demanding customers. The rim is designed and manufactured from the very beginning according to the customer's specifications. There are no restrictions on color, shape, or even the center cap. The only limitations are our imagination and budget.

Is it worth it?

If you're looking for rims that are perfect for rallying, ready to perform even in the most extreme conditions, will never let you down, and will also look attractive, then the answer is yes, forged rims are worth it. Exceptionally durable and lightweight, they enhance driving comfort and guarantee exceptional durability. For regular, everyday use, even on Polish roads, you don't necessarily need to invest in these types of products, although they can offer a lot, at a high price, of course.

Recommended

4x Kute rims 21 5x112 for MERCEDES S W220 W221 W222 W223 Long Maybach GLE GLS - LB4007

4x Kute rims 20 for BMW 3 G20 G21 4 G22 G23 G26 5 G30 G31 7 G11 8 G14 G15 X4 - CG012

4x Kute rims 20 for BMW 3 G20 G21 4 G22 G23 G26 5 G30 G31 7 G11 G12 8 G14 G15 - CG014

4x Kute rims 22 9.5+10.5 for BMW 7 G11 G12 G70 X4 M X5 G05 X6 G06 LCI X7 G07 - CG017

4x Kute rims 20 9+10 5x112 for PORSCHE Macan I II 95B FL Facelift - CG001

4x Kute rims ! 22 for MERCEDES GLE V167 53 63 AMG Coupe C167 C292 FL GLS X167 - CG033

4x new wheels Kute 21 5x130 for MERCEDES G W460 W461 W463 AMG G500 RED Line - CG033

4x Kute rims 21 for AUDI ABT S4 S5 A6 A8 Q7 RS6 C7 RS7-R SQ7 VW Touraeg II CR - CG025

4x Kute rims 20 for AUDI RS6 A4 b8 b9 S4 A5 S5 A6 A7 A8 SQ2 Q5 SQ5 Q7 Q8 Etron - CG019

4x Kute rims 22 for MERCEDES G AMG W460 W461 W463 W464 black G500 - black - LB4011

4x Kute rims 22 for MERCEDES G AMG W460 W461 W463 W464 G500 Brabus Carbon - LB4008

4x Kute rims ! 22 for MERCEDES G AMG W460 W461 W463 W464 black G500 Monoblock - LB4010

4x Kute rims 23 for LAND ROVER Discovery V Range ROVER Sport IV V L461 L494 - CG061

Modern design

Modern design Perfect fit

Perfect fit High durability

High durability Free shipping within 24 hours

Free shipping within 24 hours

Individual project

Individual project Dedicated caregiver

Dedicated caregiver