Uncomfortable vibrations on the steering wheel.

Who of us does not know the vibrations that are typical for a damaged tire or unbalanced wheels that are felt on the steering wheel while driving? Almost everyone who spends more than a few hours a month behind the wheel, whether while shopping in a supermarket or taking a trip to the swimming pool with children, knows how uncomfortable it is to drive with a vibrating steering wheel. What causes this condition? Can it be avoided quickly? What are the results? And what to pay attention to when balancing wheels? We will try to answer these questions in the article below.

Where are the vibrations on the steering wheel coming from?

The vibrating steering wheel is not reserved either for old cars or the cheapest ones. It can occur with almost every driver who, as a result of bad luck or inappropriate work of a car mechanic, goes on a road with a car that is not fully functional. As soon as he feels that the steering wheel starts to tremble or shake dangerously, he should remove the fault as soon as possible. The reasons for the formation of vibrations on the? Wheel? can there be plenty? neither can be taken lightly, as such behavior can have dire consequences.

If we experience a trembling steering wheel, we should observe the moment when this condition occurs. It may happen that the vibrations will only occur at a specific speed, will be accompanied by a characteristic sound, or e.g. will appear only during braking. By providing the mechanic with this type of information, we will significantly speed up his work and make it easier to make an accurate diagnosis.

Below are some of the most common reasons why steering wheel vibrations occur :

Unbalanced wheels - Unfortunately, vulcanizers take the matter of balancing lightly. Inadequate cleaning of the tire (e.g. stone flying inside) or an out of calibration machine will cause the wheel not to be balanced properly. The number of weights does not indicate a defect of the product, but may be caused by incorrect application of the tires.

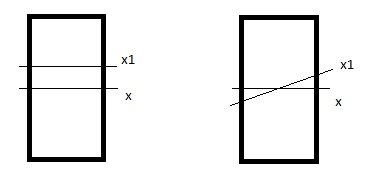

Nevertheless, we would like to explore the topic of balancing a bit more and warn customers against misunderstanding some concepts. Each rim is balanced both statically and sideways. A static unbalance is one in which the axis of rotation "wants" to move beyond the center of the rim. On the other hand, lateral imbalance is the one in which the axis of rotation "wants" to deviate from the vertical line. The situation is illustrated in the following illustration, where x is the correct axis of rotation, and x1 is the axis of apparent rotation and shifted by underweighting:

Balancing machines used in workshops are adapted to eliminate both static and lateral underweight with just a few weights. However, it should be remembered that after removing the wheel from the wheel balancer and mounting it on the car, the axis of rotation may shift slightly due to the fact that the center hole of the rim is not perfectly suited to the hub (if that were the case, we would have a problem with removing the wheel after the season), therefore even a perfectly balanced wheel on the wheel balancer can cause the bodywork to vibrate while driving. To overcome this effect, checkweighing the wheel on the car should be carried out. Nevertheless, the vibration effect in such situations is very rare, but possible. We would also like to touch on the topic of optimizing the arrangement of tires. It happens that the vulcanizer, when assembling the wheels, gives us to understand that the rims or tires may be worn, because a large amount of weights had to be used to balance the wheel correctly. Unfortunately, tire assembly workers often forget that this effect can be compensated for by moving the tire relative to the rim. Both the rim and the tire are never perfectly round and straight. The manufacturing process of each product is covered by certain standards and quality controls that assume acceptable values of production deviations. Using tires can also serrate or flatten them in only one place. All this means that both the rim and the tire have their factory underweight provided by the manufacturer. In an unfavorable coincidence, during the wheel assembly process, the above-mentioned underweight may "add up" and will require correction with a large amount of weights. In such a situation, however, the tire should be disassembled and rotated in relation to the rim by several dozen degrees, which will make the production or usage defects alleviate each other, and the amount of weights required will be significantly reduced.

The play between the car's hub and the mounted rim - Make sure that in the case of the centering ring used there is no play, both between the centering ring and the car hub, as well as the centering ring and the centering hole in the rim.

The play between the car's hub and the mounted rim - Make sure that in the case of the centering ring used there is no play, both between the centering ring and the car hub, as well as the centering ring and the centering hole in the rim.- The use of inappropriate bolts / nuts securing the rim - It should be noted whether we use mounting screws dedicated to the mounting socket of the rim.

Defective and damaged tires during operation - Even new tires, like any other product, can be defective. Yaws can be seen with the naked eye after mounting the tire on the rim, while rotating it on the wheel balancer. It should be noted that the tires do not have any bulges. Interestingly, even improper storage can affect the occurrence of vibrations, however, after driving a few hundred kilometers, this should disappear.

To learn how to properly store tires, read our article: Some tips on storing rims and tires

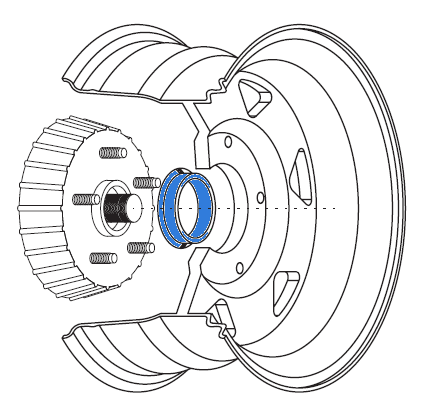

- Defective aluminum rims - Companies offering rims emphasize that the technical condition of the product should be checked before mounting the tires. It is enough to put the product in motion to see if there are any deviations. Unfortunately, some vulcanizers do it the wrong way. The most popular aluminum rims are made of the so-called low pressure method. The rim protection edge, which prevents the tire from slipping, does not have to be cast perfectly, because the tire is seated below. Observing the rim from the front, you can get the impression that the product does not keep the shape of the wheel while it rotates. In addition, rims currently available on the market in a different color finish may additionally mislead us. Experts advise to only observe the tire mounting location. This place is additionally milled, so the form of the casting is corrected. Complaints in this respect are less than 1 in 1000 cases. Below we can see exactly where to check if the rim is curved. We emphasize, however, that the outer rim itself does not define the rim as a defective or functional product. This element is designed to keep the tire on the rim and any visual defects of this element disappear after installing the tire and then the entire wheel on the car. The same applies to the uneven varnishing of this element. This gives the effect of an oval circle, but we can only notice it by observing the rotating rim, without moving in any other plane. Therefore, we will not notice it on a moving car, but the effect may cause a false sense of the curvature of the rim when balancing. We should also pay attention to the plane of the rim, which adheres to the wheel hub and the balancing machine mounting elements. Any contamination or aluminum splinters from production should be removed from these surfaces. The rim must always be perfectly flush with the wheel hub.

Curved rims - Aluminum rims are much more resistant to dynamic impact, more durable than steel rims. Nevertheless, with aluminum rims, we use tires with a lower profile, which make us feel all the unevenness and vibrations more due to the lower amortization. A rim can be damaged in many ways:

- hitting the curb,

- driving into a larger hole in the asphalt,

- during transport by a courier company.

This is often not caught by the vulcanizer during tire assembly. Before mounting the tires, check that there are no visible mechanical damages.

- Crooked brake discs - You will feel it while braking. One reason that hardly anyone pays attention to is washing hot wheels, which can lead to the brake disc warping due to a sudden change in temperature. Strongly twisted discs will generate vibrations while driving.

- Damaged support bearing, play in the steering system and badly worn shock absorbers - An old shock absorber is not able to dampen vibrations. This can be noticed when driving on uneven terrain at higher acceleration.

- Worn, unbalanced driveshaft joints - Worn outer joint, each of us can recognize (you can hear it when cornering), while the inner joint can be felt when heavily loaded while accelerating, causing the whole car to vibrate. After subtracting the gas, the vibrations should stop.

Do you have a problem with vibrations on the steering wheel while driving? React ASAP!

If we are not experts in the field of motorization, after noticing the vibrations felt on the steering wheel, we should immediately seek the help of a car mechanic. Untreated symptoms can have a severe impact on our wallet, the steering system, suspension components such as steering rod ends, wishbones and electronics will be worn faster. There is also a tire serration and even damage to the engine suspension. We do not mention situations where the vibration is to be blamed by a tumor on the tire, an event of this type may end up losing control of the car, from which there is already a short road to a road tragedy.

Nowoczesny design

Nowoczesny design Idealne dopasowanie

Idealne dopasowanie Duża wytrzymałość

Duża wytrzymałość Wysyłka gratis w 24h

Wysyłka gratis w 24h

Indywidualny projekt

Indywidualny projekt Dedykowany opiekun

Dedykowany opiekun